Dual-Mass Flywheel to Single-Mass Flywheel Conversions

Single-Mass flywheel conversions are a popular upgrade for vehicles being used at the limit of their tow capacity regularly or are modified for increased torque.

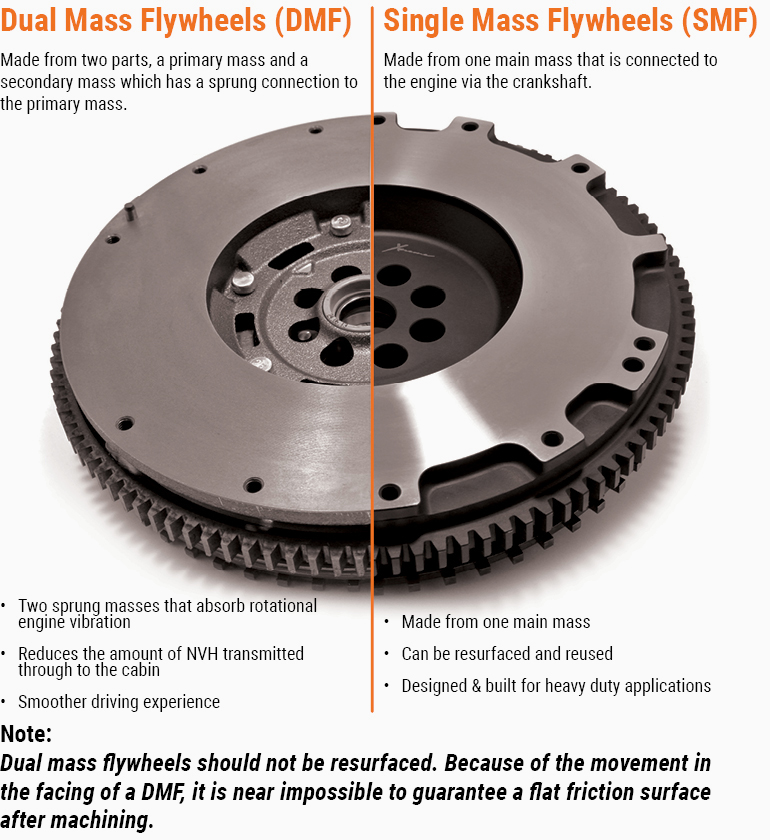

A Dual-Mass Flywheel is designed with two main parts, a primary mass and a secondary mass. These two friction surfaces are connected by arc springs designed to absorb vibration and harshness, resulting in a quieter and smoother vehicle to drive. When these flywheels are replaced with a Single-Mass alternative, there is normally an increase in Noise, Vibration and Harshness (NVH) through the cabin. Xtreme Outback dedicate extensive research and development to reduce the increase in NVH when designing the Single-Mass Conversions, often by utilising a wide angle damper and silent type idle noise suppression springs. Whilst this increase in noise is often apparent, many choose to install a conversion flywheel due to reliability in modified vehicles or vehicles that are regularly used at their limits. It is also possible to resurface a Single-Mass Flywheel whereas a Dual-Mass Flywheel will need to be replaced more regularly and at a higher cost. Dual-Mass Flywheels cannot be machined due to the movement of the facing making it near impossible to guarantee a flat friction surface.

As heavy duty clutch upgrades are designed for vehicles with performance modifications, nearly all Xtreme Outback kits designed to fit vehicles with a factory Dual-Mass Flywheel are designed to be installed on a Single-Mass Conversion flywheel.

Each vehicle responds to a Single-Mass conversion differently so if you have any questions about your specific application, please contact our friendly sales team HERE for advice.